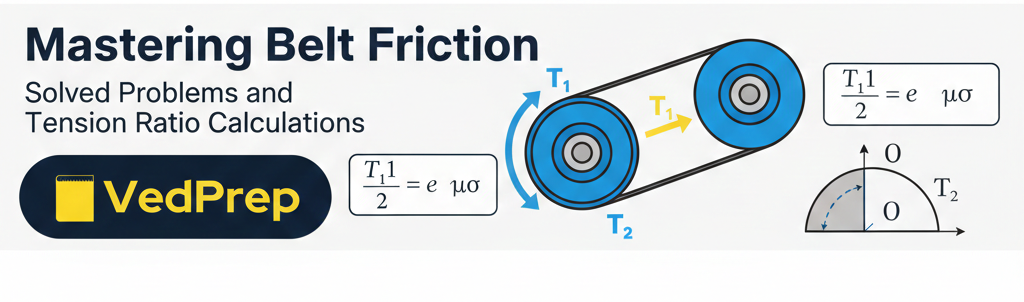

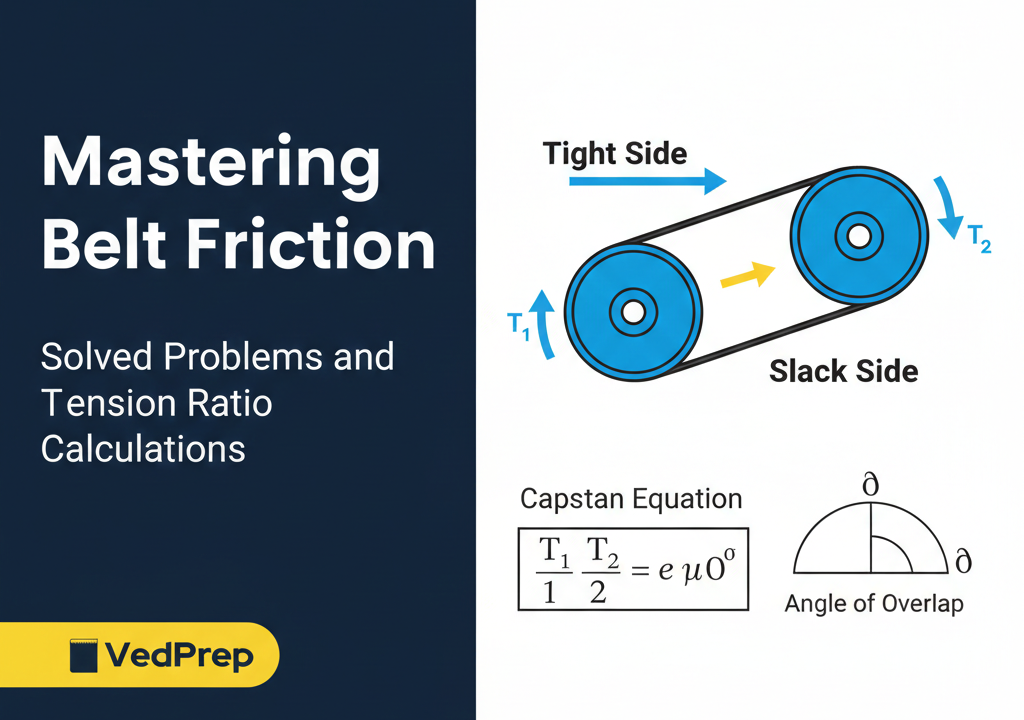

The belt friction is a force of resistance that is generated between a belt and a curved surface like a pulley or a drum. It is explained using the Capstan equation, which shows how the ratio of tensions in the tight side and slack side is determined depending upon the coefficient of static friction and angle of lap.

If you are a student aiming for an M.Tech from IIT, knowledge of the details of belt friction is not optional. Whether it is a university test or a competitive exam, comprehension of tension in drive systems is a basic knowledge requirement in mechanical

Understanding the Mechanics of Belt Friction and Power Transmission

In the realm of mechanical engineering, belt friction remains the unsung hero that enables power transmission. Consider a motor turning a pulley, for example, and without belt friction, all that would happen is that the belt would slip, accomplishing no work.

When a belt wraps around a pulley, the effectiveness of torque transfer depends on two main factors:

- Contact Area: How much of the belt is actually touching the pulley.

- Gripping Force: The physical “stickiness” or friction between the belt material and the pulley surface.

In a typical setup, the belt has a “Tight Side” ($T_1$) and a “Slack Side” ($T_2$). To Prepare GATE along with College effectively, you must realize that the driving force isn’t just one tension—it is the difference between $T_1$ and $T_2$.

The Capstan Equation Formula and Belt Tension Ratio

The mathematical heart of belt friction is the Capstan Equation (or Eytelwein’s formula). This formula allows us to predict exactly when a belt will start to slip.

Key Components of the Formula

The relationship is expressed as:

$$\frac{T_1}{T_2} = e^{\mu\theta}$$

| Variable | Definition |

| $T_1$ | Tight side tension (Newtons) |

| $T_2$ | Slack side tension (Newtons) |

| $\mu$ | Coefficient of static friction in belts |

| $\theta$ | Angle of overlap (must be in Radians) |

This logarithmic relationship indicates that a minute increase in the angle of overlap or the coefficient of static friction in the case of belts is all it takes to result in a dramatic increase in the load that the system can handle. This explains why idler pulleys in machines are used to increase the belt tension ratio in many machines of this type.

Analyzing the Angle of Overlap and Coefficient of Friction

That is where the magic occurs. On a typical two-pulley system, it is usually the case that a smaller angle of overlap occurs on a smaller pulley. That makes the small pulley “the weak link” in a belt drive system, where most slippages and creeps occur.

However, friction isn’t just about geometry. The coefficient of static friction in belts plays a massive role.

- Environmental Factors: Oil, moisture, or even heavy dust can lubricate the surface, causing the coefficient of static friction in belts to plummet.

- Material Selection: Engineers often use rubber-on-steel or specialized coatings to ensure belt friction remains stable across different temperatures.

For those looking into advanced research or standardization, you can refer to technical guidelines on mechanical components at the National Institute of Technology (NIT) or official engineering repositories.

Flat Belt vs V-Belt Friction: Which is Better?

Choosing between flat belt vs v-belt friction profiles is a classic engineering trade-off.

| Feature | Flat Belt | V-Belt |

| Grip Mechanism | Surface Friction | Wedging Action |

| Effective Friction | Standard $\mu$ | $\mu / \sin(\alpha)$ |

| Space Efficiency | Low (needs large pulleys) | High (compact) |

| Maintenance | Easy to replace | Requires grooved pulleys |

While flat belts are simple, V-belts use a “wedging” effect in the pulley groove. This trick effectively multiplies the coefficient of static friction in belts, allowing for a much higher belt tension ratio without needing a massive angle of overlap.

Centrifugal Tension Effects in High-Speed Drives

When machines spin at thousands of RPMs, centrifugal tension effects become a problem. As the belt travels fast, it literally tries to fly off the pulley due to centrifugal force.

- The Physics: This force reduces the contact pressure between the belt and pulley.

- The Math: Centrifugal tension ($T_c$) is calculated as $T_c = mv^2$.

- The Impact: When solving belt friction problems, you must subtract $T_c$ from the total tension to find the “effective” tension available for friction.

If you don’t account for centrifugal tension effects, your belt will slip at high speeds, even if it feels tight when the machine is turned off!

Solving Belt Friction Problems: Quick Step-by-Step

If you are learning How to attempt GATE 2026, you need a reliable method for these problems:

- Identify $T_1$ and $T_2$: Remember, $T_1$ is the side that pulls the load.

- Convert to Radians: If the angle of overlap is in degrees, multiply by $\pi/180$.

- Calculate the Ratio: Use $e^{\mu\theta}$ to find the maximum belt tension ratio.

- Factor in Speed: If the belt is moving fast, calculate centrifugal tension effects ($mv^2$).

- Check for Slip: Ensure the required tension doesn’t exceed the friction limit.

For deeper practice, checking out Vedprep GATE Exam Preparation resources can provide you with a library of solved examples.

Conclusion

The understanding of belt friction includes more than mere memorization of the formula of Capstan’s Equation; it’s about balancing the angle of overlap, managing centrifugal tension effects, and knowing the difference between flat belt versus V-belt friction. By mastering these tension calculations, you ensure that your mechanical systems are efficient, durable, and slip-free.

Ready to take your preparation to the next level? Start your journey with Vedprep GATE Exam Preparation today and turn these complex formulas into your strongest exam assets!

Frequently Asked Questions (FAQs)

What is the primary cause of belt friction?

Belt friction is caused by the microscopic irregularities between the belt material and the pulley surface, which resist relative motion.

How does the angle of overlap affect belt friction?

The larger the angle of overlap, the more surface area is in contact, leading to an exponential increase in the belt tension ratio.

What is the difference between slip and creep in belt drives?

Slip is a total failure of belt friction where the belt slides over the pulley. Creep is a natural, small stretch/contraction of the belt due to tension changes.

Why is the Capstan Equation formula important?

The Capstan Equation formula allows engineers to calculate the exact tension needed to transmit power without slipping.

How do centrifugal tension effects impact high-speed belts?

Centrifugal tension effects reduce the effective gripping force of the belt by pulling it away from the pulley surface at high velocities.